Getting better energy efficiency out of hydraulic systems matters more now than ever before because energy prices keep climbing and people care a lot more about what happens to the environment these days. Some studies show that hydraulics alone eat up around 30 percent of all energy used in factories across the country. That's why there's so much talk about making these systems work smarter not harder. Companies want to save money on their electricity bills obviously, but they also face pressure from customers and regulators who expect them to cut down on greenhouse gases. The push for greener operations isn't just good for the planet either it makes financial sense too when looking at long term savings.

Getting better at managing energy in hydraulic systems saves money and makes everything run smoother. The US Department of Energy did some research showing that when companies tweak their hydraulic systems properly, they cut down on power usage by around 70%. That means lower electricity costs for sure, but there's another benefit too – parts last longer because they don't get worn out so fast. Looking closely at all the pieces that make up these systems works wonders. Pumps, motors, control mechanisms – each one matters. Many shops are now installing newer tech solutions such as variable speed drives alongside high efficiency pumps. These upgrades aren't just theoretical improvements either; plenty of manufacturers report noticeable differences in both bottom line numbers and equipment reliability after making these changes.

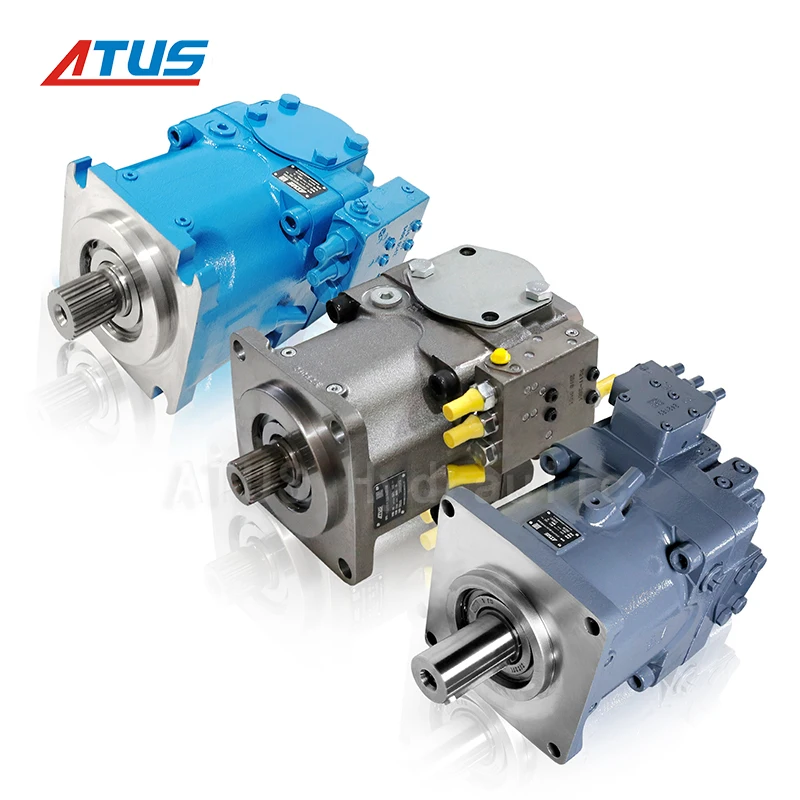

The type of hydraulic pump used makes all the difference when looking at how much energy gets consumed in these systems. Variable displacement pumps stand out as the most efficient option available today. What sets them apart? Well, they basically adjust what they put out depending on what's needed at any given moment. They only create flow when there actually is a need for it, whereas fixed displacement pumps keep running nonstop regardless of demand. Manufacturers across the industry report that switching to variable displacement models cuts down energy consumption somewhere around 30% compared to those old fixed ones. For facilities dealing with changing workloads throughout the day, this kind of adaptability really pays off. Less wasted energy means lower bills month after month, something plant managers definitely appreciate during budget reviews.

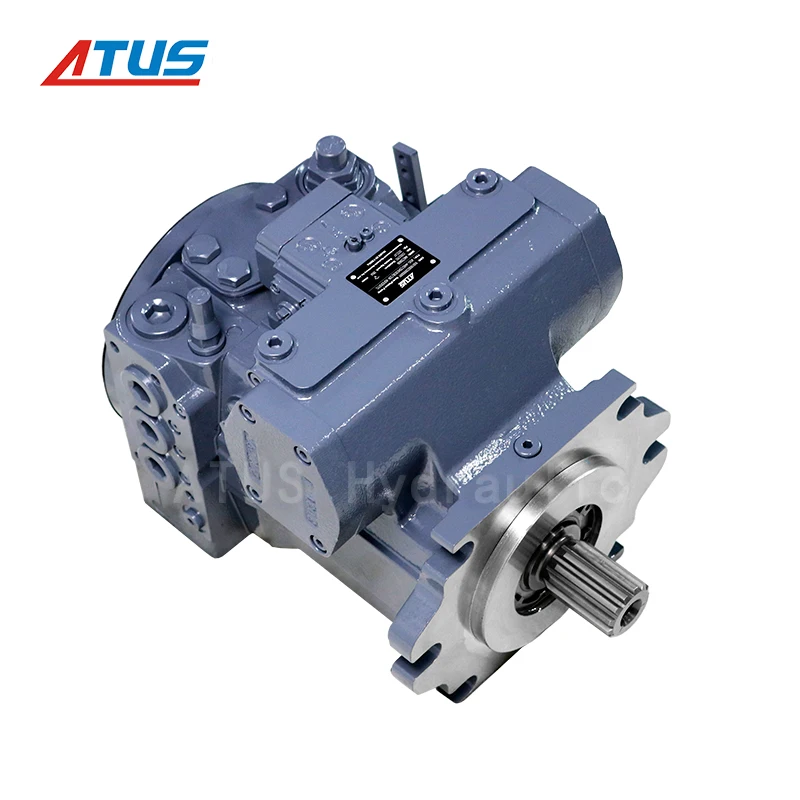

Hydraulic motors are really important when it comes to improving how efficiently a hydraulic system uses energy, especially with all the new design improvements we've seen recently. Many of these newer motors come equipped with things like load sensing technology and special materials that cut down on friction, both of which help save power. Take the axial piston motor for instance, this particular type has become pretty popular because it actually conserves a lot of energy during operation. What makes these motors stand out is their ability to deliver strong torque even when running at slower speeds. Compared to older versions from just a few years back, the efficiency numbers look much better now. For companies looking to slash their energy bills, switching to these modern hydraulic motors often makes good business sense while also being kinder to the environment.

Choosing the correct hydraulic cylinders makes all the difference when it comes to cutting down on energy usage. When designing systems, factors like using lighter weight materials and applying special coatings to cut friction matter a lot. Some top quality cylinders now come made from composite materials which means they weigh less while lasting longer, so they eat up less power overall. Take for instance cylinders with special low friction coatings these days require far less power just to get moving, which helps boost how well whole systems perform. Businesses that focus on getting this right tend to save money on their energy bills plus enjoy longer lasting equipment with fewer breakdowns and repair needs over time.

Design strategies that focus on boosting energy efficiency really matter when it comes to hydraulic systems. The main tactics involve optimizing how things are laid out and making sure components work together well, something most industry standards already cover. When engineers arrange parts in ways that cut down on wasted energy and get all those pieces talking to each other smoothly, the whole system runs better. We've seen energy bills drop significantly while systems last longer without breaking down. Following ISO guidelines isn't just good practice it's practically a roadmap for saving money on power costs. Many plants report cutting their energy usage by double digits once they start following these best practices seriously.

Putting inverter drives into hydraulic systems brings real advantages when it comes to saving power. What these drives do basically is control motor speeds and adjust according to different workloads, which means less wasted energy overall. Some research indicates that switching to inverter drives can cut energy bills by around 20%. The money saved happens because they don't keep running at full blast when there's not much demand for hydraulic power. Many factories have already installed them and seen their electricity costs drop significantly. For manufacturers looking to trim expenses without sacrificing performance, this makes sense both financially and environmentally. Companies adopting this technology often find themselves hitting multiple targets at once – cutting down on carbon footprint while also seeing better bottom line results from reduced utility spending.

Keeping up with regular maintenance makes all the difference when it comes to energy efficiency in hydraulic systems. When technicians check these systems on schedule, they spot problems early on such as leaks, worn parts, or degraded fluids before things get really bad. This proactive approach keeps everything running smoothly without unnecessary strain on components. Research indicates that companies sticking to maintenance schedules tend to save money on energy bills because their machines work better when properly maintained. A solid maintenance strategy not only cuts down on operating expenses but also means hydraulic equipment lasts longer than it would otherwise. Many manufacturers report significant savings after establishing proper inspection routines across their facilities.

Quality hydraulic fluids play a major role when it comes to getting better energy efficiency out of equipment. These premium grade fluids do several things at once they lubricate better, cut down on friction points, and help prevent premature wear across various parts of the system. All these factors work together to boost performance levels while making the whole operation more energy efficient. Most maintenance manuals will point toward certain fluid specifications, looking for the right balance between viscosity and how well they hold up under heat stress. This matters because poor choices here can lead to breakdowns down the road. When businesses invest in proper hydraulic fluids, they typically see real reductions in power consumption over time, plus their systems tend to run smoother and last longer between repairs.

Looking into modern hydraulic equipment often turns up ways to cut energy costs and boost how systems actually perform on site. Take the Axial Piston Pumps model A11VO130 for instance they fit right into CAT wheel excavators and deliver impressive results. What makes these pumps stand out? They run efficiently without making much noise, which matters when working near residential areas. Plus, their build quality holds up under tough conditions day after day. Construction companies across different sectors have found these pumps work well beyond just excavators. While they do cost a bit more upfront than standard models, many operators report significant fuel savings over time without sacrificing the reliability needed during long shifts on demanding jobsites.

Looking at practical fieldwork, the Parker P24S Pump used with CAT D6 RotoSlasher machines really stands out when it comes to getting things done efficiently. What makes this pump special is how it actually recovers some power during those heavy load situations, cutting down on wasted energy and saving money over time. Operators love the different ways they can control this unit, plus it just keeps performing reliably even under tough conditions. Many maintenance teams have noticed significant improvements in their overall system efficiency since switching to these pumps, especially in operations where every drop of fuel matters.

The ATUS A4VG Hydraulic Pumps really shine when it comes to running efficiently while packing a lot of power into their compact design, which honestly sets them apart from most competitors on the market today. What makes these pumps so versatile is how they come equipped with various control options that work well across different industrial settings, from manufacturing plants to construction sites. The engineering behind these units actually delivers superior performance metrics than what we typically see from other brands in this category, making them a smart investment for businesses looking at long term cost savings and reduced maintenance needs.

Embracing energy-saving technologies in hydraulic systems is crucial for sustainability and financial benefits. These advancements significantly reduce energy consumption, decrease environmental impact, and provide substantial long-term economic advantages. The implementation of such technologies is essential for industries aiming to improve their overall operational efficiency while conserving resources.

The field of hydraulics keeps moving forward with new ways to save energy across the board. We're seeing companies adopt smarter systems these days, ones that adjust better to different conditions while using less power. Many manufacturers are now integrating advanced controls into their equipment alongside greener materials for construction. Those who invest early in these improvements position themselves well for ongoing gains in efficiency. After all, nobody wants to be left behind when it comes to making hydraulic tech work harder with less environmental impact.