The technology behind hydraulic pumps makes all the difference when it comes to getting systems to perform better, reliably delivering both efficiency and dependability across countless applications. These pumps sit at the heart of numerous mechanical setups, basically converting fluid power into actual movement we can see and feel. Their efficiency matters a lot too, whether we're talking about heavy industrial equipment or smaller items most people encounter daily, think gas station fuel dispensers or even modern dishwashers. To really get good with this stuff, one needs to know about the main categories of hydraulic pumps out there. There's gear pumps which tend to show up in simpler systems where the center remains open during operation. Then there are piston pumps that pack quite a punch when it comes to generating serious pressure levels needed for tougher jobs. Each type has its own sweet spot depending on what exactly needs to be accomplished in any given situation.

When it comes to making pumps work better, innovation in their design plays a big role. We see this happening all over the industry, especially with firms like ATUS working on real world applications. New materials are coming into play alongside clever design changes that actually make a difference in how pumps perform. But getting good at these tech advances isn't easy. There's a learning curve involved, from understanding specialized knowledge to keeping up with what engineers consider best practices today versus yesterday. True mastery means going beyond just applying what already exists. It requires thinking outside the box and creating custom solutions that meet needs as they change over time, something many manufacturers struggle with but must tackle if they want to stay competitive.

Knowing how gear oil systems differ from electric hydraulic applications makes all the difference when trying to get them running at peak performance. Gear oil pumps tend to show up wherever proper lubrication matters most, like in machines with lots of moving components. Electric hydraulic pumps, on the other hand, offer something different altogether they give operators fine-grained control plus better energy savings, which explains why they're so popular in automated manufacturing and even space exploration equipment. What works best really depends on what each system brings to the table. At ATUS, we've developed several ways to tweak these systems for better results. Our approach focuses on making individual parts work harder for their money and ensuring everything connects properly without unnecessary complications.

In several recent client projects, ATUS has managed to optimize systems quite effectively, particularly when integrating electric hydraulic pumps into logistics automation setups. These improvements have led to real energy savings for companies and cut down on their day-to-day expenses. Getting good results from such integrations demands attention to detail regarding component compatibility across different parts of the system. When everything works together properly, it makes a noticeable difference in how smoothly operations run. The company keeps improving its approach to system integration, which explains why many manufacturers now turn to them for help with hydraulic system optimization. This ongoing refinement not only boosts reliability but also helps maintain consistent performance levels across a wide range of industrial applications.

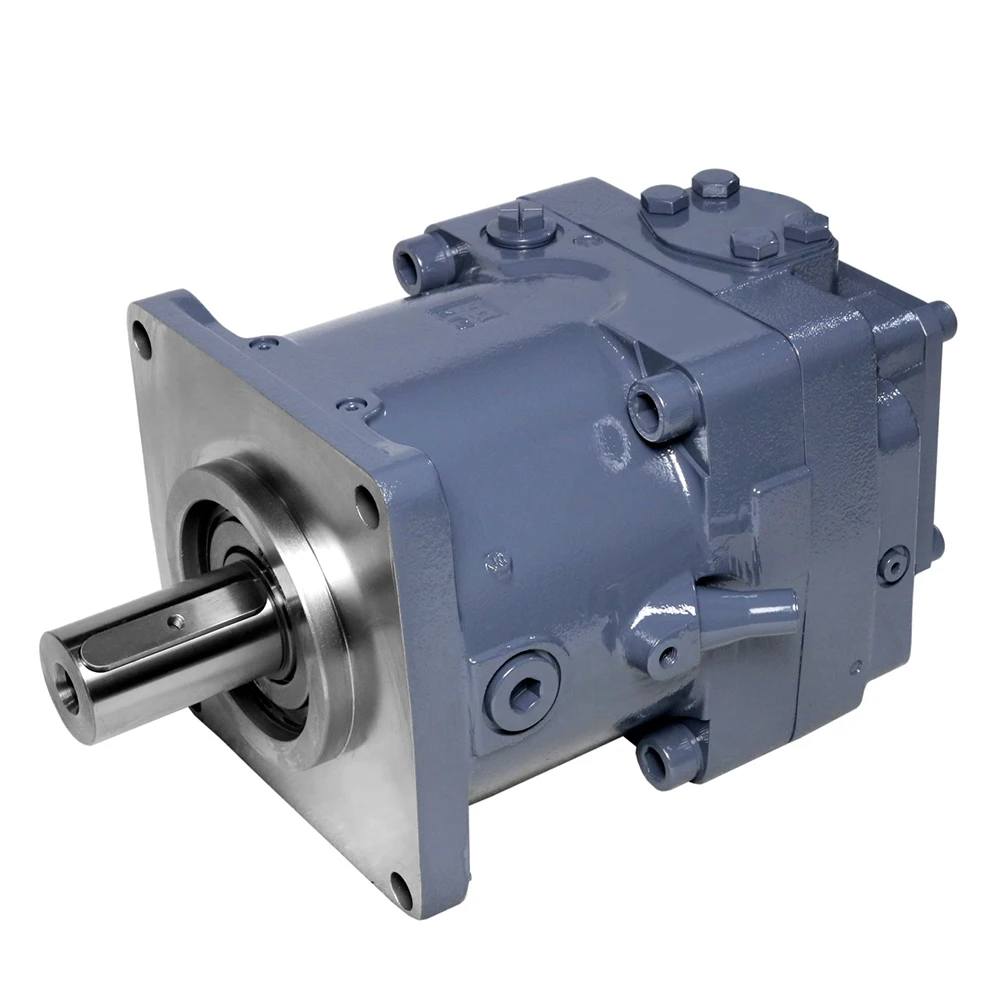

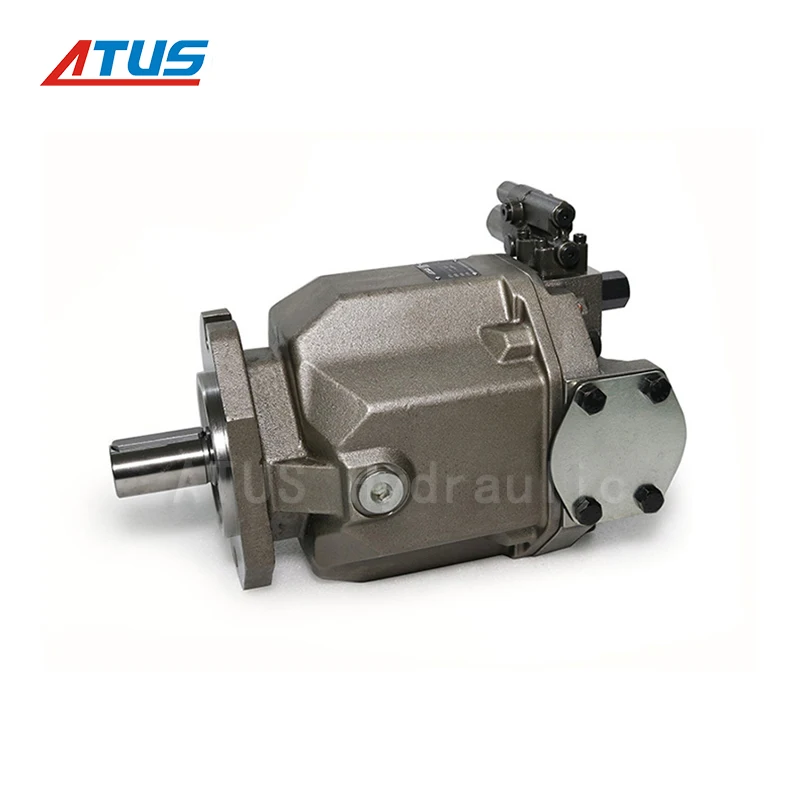

The A4VG Series piston pumps form a key part of ATUS hydraulic systems, used extensively throughout various industrial settings. These pumps stand out because they work so efficiently and can be adapted for different purposes, which is why they show up everywhere from construction sites to factory floors. What makes these pumps special? They can handle serious pressure levels while still maintaining good flow rates, something that explains why they're popular worldwide. Many customers report that these pumps keep going even when things get tough on site. Looking ahead, ATUS continues to tweak and upgrade the A4VG models based on what users tell us plus incorporating new tech developments. The goal stays simple: better performance without sacrificing reliability.

The ALA10VO60 pump is pretty much the go-to choice when it comes to medium pressure applications, offering real benefits that make a difference in day to day operations. We see these pumps working hard in places like hydraulic drilling equipment and those big forklifts at warehouses. What makes them special? Well, they have this great flow control system that adapts to different needs while their build quality just keeps going strong even under tough conditions. Mechanics who've tested them over time report consistent results week after week, which explains why so many professionals keep coming back to this model. Plus, it ticks all the boxes for important industry certifications and safety requirements, something that gives plant managers peace of mind knowing their investment will hold up across construction sites, manufacturing floors, and other demanding environments where reliability matters most.

The heavy-duty nature of track-type tractors means they need special hydraulic systems that can handle tough jobs day after day, which is where ATUS steps in with its custom made parts for this market. When making components for these machines, engineers face real problems like keeping everything working properly when temperatures swing from freezing cold to scorching hot. ATUS tackles these issues head on using smart design techniques that have stood up well in practice. Farmers in Nebraska and construction crews in Alaska have reported great results with ATUS parts lasting through brutal seasons. Working alongside top names in farming equipment and earthmoving machinery helps ATUS stay ahead of industry needs while constantly improving what they offer. Their products just keep getting better because they know exactly what works out there in the field.

Overall, ATUS demonstrates a commitment to delivering comprehensive hydraulic solutions designed to meet the evolving needs of various industries. Through technological innovation and strategic partnerships, ATUS continues to advance as a leader in hydraulic system excellence.

In the last ten years or so, closed circuit transmission tech has really come a long way, and ATUS has been at the forefront of most of these changes. What we're seeing now is better performance across the board plus much improved energy efficiency, which matters a lot for those working with hydraulic systems day in and day out. Looking at numbers from ATUS research departments, they claim their latest models cut down on machine downtime by around 40%, something that speaks volumes about how reliable and efficient these systems actually are. The folks at ATUS have spent years developing special technologies and securing patents for various components within their transmission systems, giving them a strong position in this particular segment of industrial equipment manufacturing.

Let's look at how they've actually applied this innovation through their patented designs that work right alongside hydraulic pumps, boosting both power and efficiency in real world applications. The company keeps pushing boundaries in the field, setting new standards that other manufacturers have to catch up with. Their hydraulic systems are built to handle what modern operations need, especially those focused on saving energy costs. What makes ATUS stand out in hydraulic research and development? Well, they're constantly coming up with improvements that aren't just incremental changes but actual game changers for the whole industry standard.

The way swashplates are designed really matters when it comes to how well hydraulic pumps work, and ATUS has become pretty good at making these components better using smart approaches. When companies optimize their swashplate designs, they see real gains across multiple areas - things get more efficient, parts last longer, and overall system performance improves significantly. ATUS uses some pretty sophisticated techniques for refining their designs, combining computer modeling with physical prototypes to test out different configurations. Looking at actual performance metrics tells another story too. Customers report seeing noticeable increases in fluid flow rates while experiencing far less component wear after switching to ATUS optimized swashplates. These practical improvements translate into tangible benefits for equipment operators who need reliable hydraulic systems day after day.

When compared against what's typical in the industry, ATUS has really pushed the envelope with their swashplate designs. These aren't just theoretical improvements either they actually work well in practical situations across various industries. The level of precision built into these components means operators get much better control over fluids flowing through hydraulic systems. What's more, ATUS works closely with several independent engineering laboratories to put their designs through extensive tests and validations. This approach isn't just about meeting minimum requirements but going above and beyond industry benchmarks. By focusing so intensely on optimizing every aspect of their designs, ATUS continues to deliver high quality hydraulic solutions that set new standards in performance while maintaining reliability. Their dedication to excellence helps explain why they keep growing stronger in a competitive market landscape.

What sets ATUS apart in construction and agriculture is its ability to tailor hydraulic systems for each industry's unique requirements, which makes their equipment adaptable while boosting efficiency across the board. Farmers and builders need gear they can trust day after day, and that's exactly what ATUS delivers through products ranging from high-performance hydraulic pumps to robust ram systems that keep machines running smoothly. Take a recent case study from rice fields in Southeast Asia where local farmers struggled with inconsistent yields. After installing ATUS custom hydraulics, those same fields saw crop output jump by around 20% just twelve months later because the machinery worked better under tough conditions. Sure, there are always headaches dealing with unpredictable weather patterns and fluctuating workload demands, but ATUS has cracked the code through creative engineering and working hand-in-hand with customers throughout the process. The result? Machines that perform reliably even when things get rough, and a growing list of satisfied clients who now consider ATUS the go-to name for specialized hydraulic solutions.

When it comes to integrating hydraulic systems into complex industrial machinery, there are plenty of hurdles to overcome. Still, ATUS has managed to deliver solid results time after time. Their work with various partners has led to some pretty impressive outcomes across different industries. Take their collaboration with a major German carmaker for example. After implementing their hydraulic solutions, the factory saw a boost of around 15% in production output simply because equipment breakdowns dropped significantly. Industrial customers consistently report better performance metrics and fewer system malfunctions when working with ATUS on hydraulic projects. These real world improvements haven't gone unnoticed either. The company regularly receives accolades in the field of hydraulic engineering, which speaks volumes about their dedication to both innovation and maintaining high standards within manufacturing environments.