ATUS provides everything customers need for hydraulic systems all in one place. We start by sitting down with clients to really understand their specific requirements and challenges. From there, we move through the whole process together - designing solutions that fit their space constraints, building components according to their specs, right down to putting everything together properly. Each step along the way meets both what the customer wants and the necessary safety standards too. After delivery isn't where our relationship ends either. We make sure people know how to operate their equipment correctly, help fix any issues that come up, and keep user guides readily available. Our ongoing support shows just how seriously we take making sure customers get real value from their investment over time.

ATUS focuses on getting the most out of system performance by incorporating hydraulic pumps and motors right into the core design process. They spend time picking the right pump motor combos for each job based on what works best in practice. For visualizing how everything fits together, engineers rely heavily on computer aided design software. These CAD tools help map out where components should go, saving space in tight areas while making sure things actually work properly when installed. Getting all these parts to play nice together matters a lot too. When pumps, motors and the rest of the system mesh well from day one, it cuts down on repairs later on and extends how long equipment lasts before needing replacement. The whole approach leads to better hydraulic systems capable of handling tough real world conditions without breaking down so often.

When companies need hydraulic systems that fit their exact requirements, custom designs become essential across different industrial fields. These made-to-order setups address specific challenges faced by manufacturers, power plants, and many other businesses day after day. Take factories for example where customized hydraulics can really ramp up production while slashing expenses on maintenance and downtime. Power generation facilities see similar benefits too, with specialized systems helping manage resources better and minimizing unnecessary losses. Getting everyone involved during development makes all the difference. Good engineers don't just build what they think clients want but actually talk to them regularly throughout the project. This back and forth helps tweak designs as needed so when the final system arrives at the customer site, it works exactly how it should without any surprises down the road.

Getting the most out of an oil pump makes all the difference when designing circuits that work well over time. The right choices matter a lot - things like displacement rates and pressure settings need matching up with what the circuit actually requires for better operation down the road. Most engineers run computer models while they're still planning everything out. These simulations help adjust important stuff like how thick the oil gets at different temperatures and just how fast the pump should spin for maximum results. Don't forget about outside factors either. Look at where the system will be installed and check if there might be dirt or other particles getting into the oil supply. This kind of thinking keeps circuits running reliably year after year. Systems built this way tend to last much longer without breaking down unexpectedly.

ATUS focuses on creating top quality hydraulic parts by following strict German DIN standards that cover everything from how well things work to making sure workers stay safe. These standards matter because without them, components might fail when put under real world stress in factories and plants across the country. When ATUS gets those official quality seals, it really makes a difference in what customers think about our products. People want to know their equipment won't let them down during critical operations. We also do regular checks throughout our facility to make sure we're always meeting those same high standards. This constant oversight helps keep our manufacturing running smoothly year after year, which is why so many companies turn to ATUS whenever they need dependable hydraulic solutions for their heavy duty machinery.

Before any hydraulic cylinder leaves the facility, it goes through all sorts of tough tests to make sure they last long and work well even when things get rough out there. We run pressure checks and do those fatigue tests that basically push them to their limits just to see how strong and resilient these cylinders really are over time. Keeping track of all these test results helps us show we meet those tough industry standards, something that actually cuts down on warranty problems and makes customers happier overall. The fact that we spend so much on fancy new testing gear says a lot about our dedication to making reliable products. Clients know this means business, and they trust that our hydraulic cylinders will stand up to whatever challenges come their way.

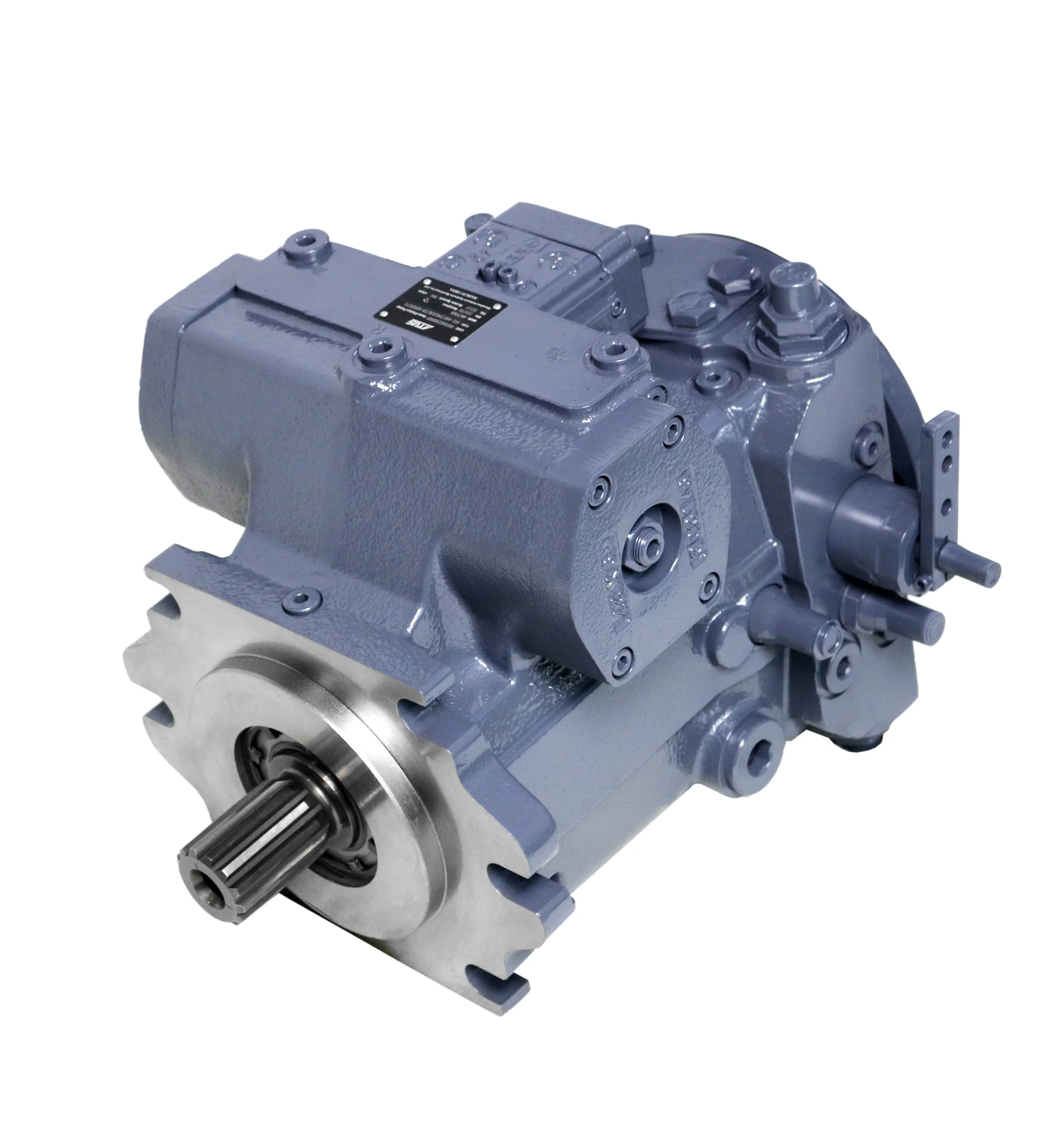

The A4VG Series stands out in high displacement scenarios thanks to some seriously smart engineering behind the scenes. These pumps shine especially well in those closed circuit setups common in heavy duty vehicles and factory floor equipment because they transmit power so efficiently while wasting next to nothing in terms of energy. Let's look at the numbers: displacement ranges from 28 all the way up to 250 units, torque capability jumps from 79Nm right through to 400Nm, and fluid flow can handle anything between 119 liters per minute and a solid 600 LPM. What does this mean practically? Longer lasting operation under tough conditions where downtime costs money. We've seen these pumps hold up remarkably well in construction sites and manufacturing plants where reliability isn't just nice to have it's absolutely essential.

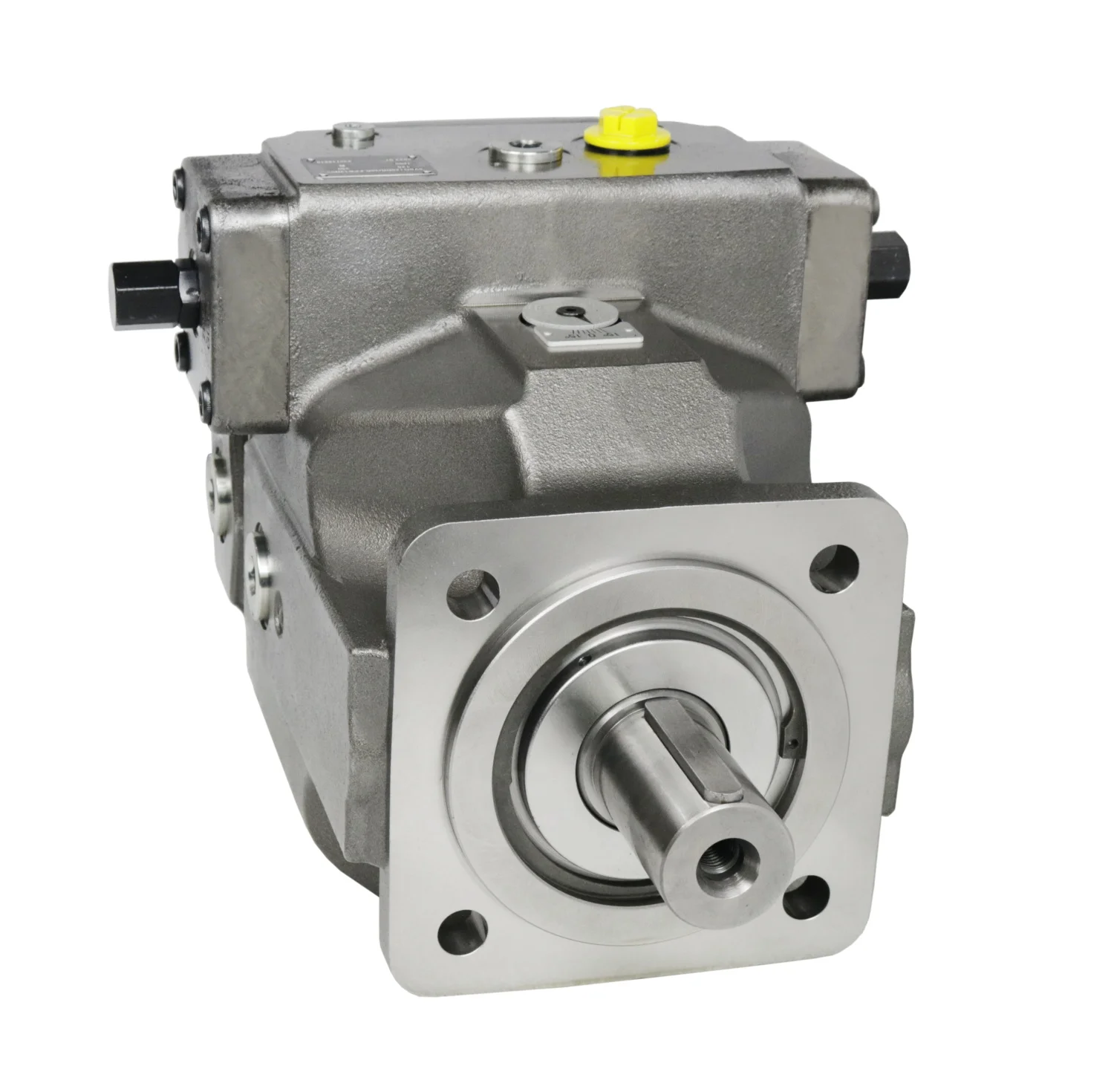

The A4VSO series handles all sorts of hydraulic tasks thanks to solid performance even at extreme pressures of around 350 Bar. What makes these units stand out is their variable displacement feature which lets operators control oil flow smoothly no matter what the situation demands. They work well with most standard hydraulic setups, so installation isn't too complicated. The displacement range goes from 40 right up to 1000, giving engineers plenty of flexibility when designing systems. Because of this wide range and pressure handling capability, many manufacturers choose A4VSO pumps for their open circuit systems in heavy industries where reliability matters most.

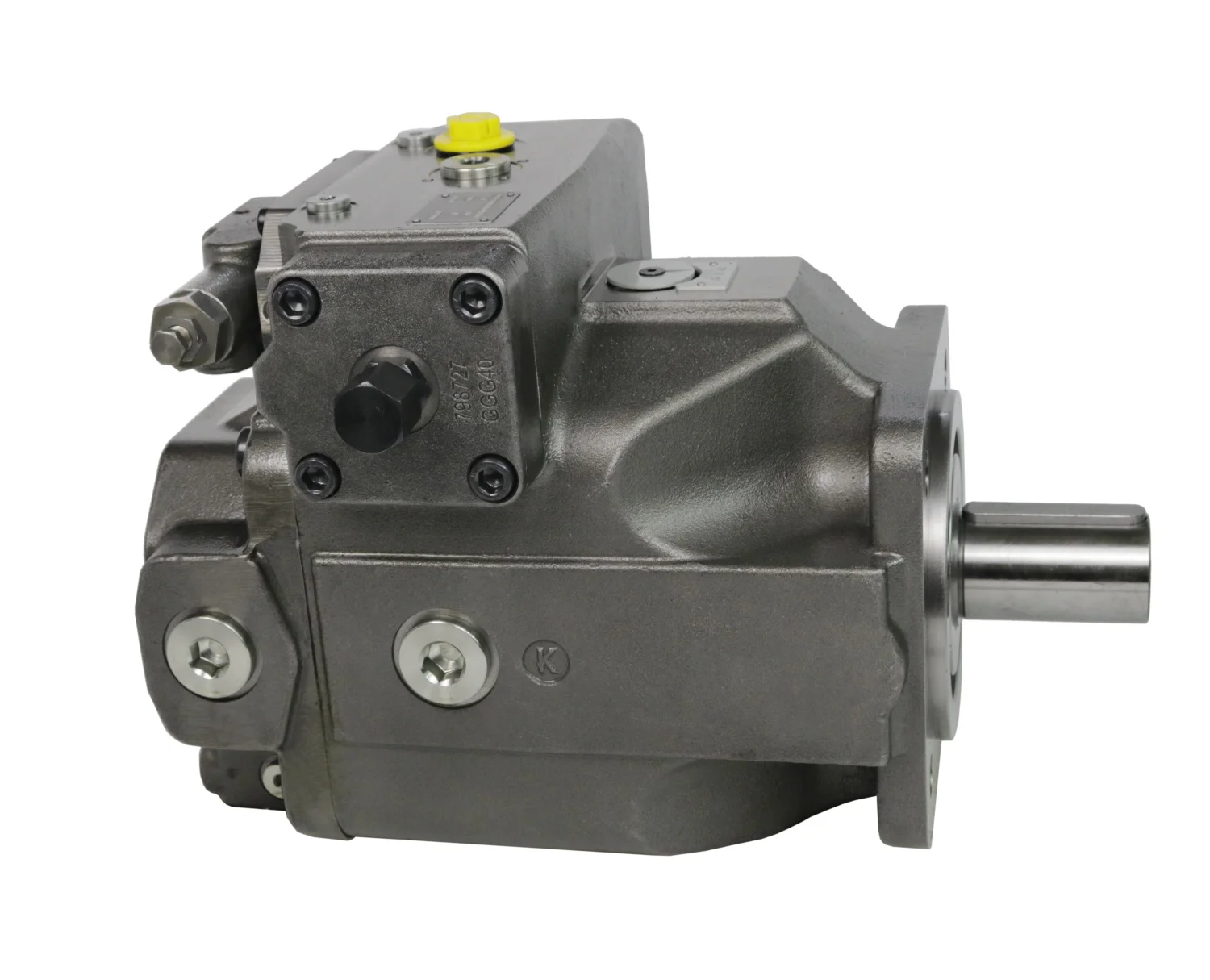

Built for the tough realities of mining work, the A4VSO500LR2D model stands up against the brutal conditions found in mines while maintaining impressive pressure resistance. The unit's sturdy build handles massive loads without breaking down, even when exposed to dust, vibrations, and temperature extremes common in underground operations. Mining companies across Australia and South America have reported outstanding results after switching to this equipment, noting fewer breakdowns during peak production periods. With specs that include reinforced components and advanced sealing systems, this model delivers what mining operators need most day after day in some of the world's harshest industrial settings.

ATUS built out a strong worldwide technical support network so customers get help when they need it most, which really boosts their confidence in our products. We've got all sorts of tools available including detailed online resources, step-by-step troubleshooting guides, plus direct lines to our team of hydraulic specialists who can tackle almost any problem quickly. Since rolling out this support system, we've seen something pretty impressive happen. Customer satisfaction scores jumped quite a bit after implementing these changes, with many clients leaving glowing reviews about how much easier things became for them. All told, this whole support infrastructure makes ATUS stand out as someone businesses can count on day in and day out without worrying about operational hiccups.

ATUS stands out in the industry because they actually deliver spare parts on the same day, which means hydraulic systems stay running instead of sitting idle. Their warehouse operations are pretty impressive too - everything is organized so efficiently that parts can be shipped fast when needed. This gives them a real edge over competitors who might take days to get parts out. Industry stats back this up showing companies with quick response times tend to perform better operationally. What really sets ATUS apart though is how seriously they take their customers' problems. When clients need something urgent, ATUS goes above and beyond what most suppliers would do, making sure equipment gets back online as soon as possible.

Preventive maintenance really matters when it comes to keeping hydraulic motors running smoothly for years. The whole idea involves checking things out regularly and swapping parts before they fail. From what we've seen in the field, companies that stick to these routines save money in the long run. Fewer breakdowns mean less downtime and repairs, plus equipment lasts much longer than it would otherwise. ATUS actually compiles all sorts of practical advice on maintaining hydraulic systems, stuff that real technicians have learned from experience. Our customers find these resources incredibly helpful, especially during those tricky maintenance seasons. When businesses take care of their systems properly, everyone wins. Operators get peace of mind knowing their machinery won't let them down at critical moments, while plant managers appreciate the predictable budgeting and reduced stress levels that come with reliable operations.