A hydraulic piston pump has three main parts working together: the cylinder, the piston itself, and the housing that holds everything in place. Inside the cylinder, the piston slides back and forth, squeezing hydraulic fluid and creating pressure as it moves. Most housings are built from tough stuff like cast iron or steel because they need to handle all that pressure without failing. When these parts work properly, they turn mechanical movement into useful hydraulic force. Seals and valves play their part too, keeping fluids contained so nothing leaks out during operation. Material choice matters a lot here. Steel cylinders stand up better to wear and tear, making them ideal for heavy duty jobs in construction sites and factories where equipment gets put through its paces day after day.

Axial piston pumps create hydraulic power when pistons move along an axis inside the pump housing. The way these pumps work makes them really good at turning mechanical energy into pressurized fluid flow. When the main shaft spins, it pushes those pistons in and out of their cylinders. On one stroke they suck in oil from the reservoir, then push it out forcefully through the pressure port on the next stroke. These kinds of pumps show up all over places where serious power is needed, especially in big machines used for digging in mines or building massive infrastructure projects. Why? Because they just keep working reliably even under tough conditions while wasting less energy than other types. Real world tests have shown some models can reach efficiencies around 90% or better, which explains why so many engineers specify them whenever there's talk about getting maximum performance from limited fuel budgets.

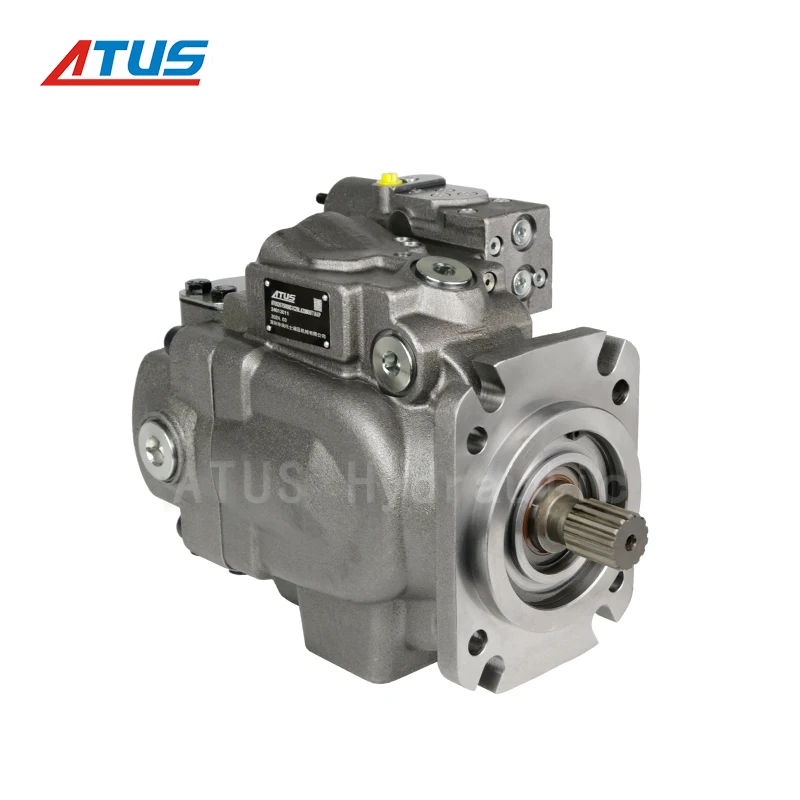

The Mud Pump Drive Pump P2 075 represents something special for folks working in mining and energy fields because of how well it performs under tough conditions and adapts to different situations. What makes this particular model stand out? It features a variable displacement system with axial pistons inside, which means operators can rely on it for medium pressure jobs reaching all the way up to 370 bar when needed. Another thing that sets it apart is the impressive speed at which it operates, so it works great in those mobile setups common across many industrial sites. Plus, the whole unit isn't taking up much space at all while running surprisingly quiet compared to similar pumps on the market today. No wonder so many technicians actually prefer using this one over others they've tried before.

The mining industry has turned to the P2 075 model because it just works better in tough conditions. We've seen this equipment running day in and day out at big mines across North America where operators report fewer breakdowns compared to older models. The pump's design cuts down on maintenance stops, which means more hours actually extracting minerals instead of waiting for repairs. People who work in the field regularly mention how dependable this system is when dealing with the extreme pressures found in underground operations. For companies looking to keep their extraction processes running smoothly without breaking the bank on constant fixes, the Mud Pump Drive Pump P2 075 has become something of a standard choice in many large scale mining projects.

The TZ2T Rock Drilling Rig comes with two main pump models, the P2105 and P3105, each packed with special features that really boost performance when drilling into tough rock formations. What makes these pumps stand out is their variable displacement system. This means operators can tweak the flow rate on the fly depending on what they're dealing with underground. When working through different types of rock layers, this kind of fine control makes all the difference. The way these pumps are built minimizes how often they need maintenance stops, something that saves time and money across the board. For companies operating in harsh environments where every minute counts, having equipment that keeps running smoothly without constant interruptions becomes absolutely essential to staying competitive.

Looking at how the P2105 and P3105 perform shows they really stand out when it comes to using power efficiently and holding up in tough situations. People who have used these machines talk about how quiet they run compared to other equipment, plus the fact that parts are easy to access for regular maintenance work. This actually saves money over time since there's less downtime needed for repairs. What makes these models particularly good for drilling jobs is their ability to keep performing reliably even when pressure levels change throughout the day. Operators appreciate this stability because it means fewer interruptions during critical operations where consistency matters most.

What really sets the P2060 series apart is how versatile and dependable it proves in all sorts of industrial hydraulic setups. The folks who work with heavy machinery know that these units handle themselves well in places like factories, building sites, and power plants where conditions can be tough on equipment. Why has this model become so popular? Well, several factors contribute to its appeal. For starters, installing them isn't a nightmare thanks to their flexible design. Plus they run surprisingly quietly compared to similar models on the market. And here's something interesting about performance too they keep going strong even when faced with those challenging high self priming speed situations that tend to trip up lesser pumps.

Industrial equipment makers love the P2060 for its dependable performance and how easy it is to maintain. The pump's compact size lasts longer than many competitors, which means factories can run smoother without constant downtime. Production costs drop when these units are installed because they require fewer repairs and last through multiple shifts. What makes them stand out? They help cut down on energy bills while still keeping operations running at peak levels. From food processing plants to chemical manufacturing facilities, companies across different sectors are finding that switching to P2060 pumps pays off both financially and operationally over time.

Hydraulic ram pumps are really important for how heavy machinery works, making sure all those hydraulic systems run smoothly so machines perform at their best. Found in everything from excavators to harvesters, these pumps transmit power efficiently while letting operators control movements precisely. Big names across construction sites, mines, and farms depend on them to keep their equipment running strong. Take Caterpillar and Komatsu for example they've built these pumps right into their machines because they know what makes a difference on site. Real world tests show machines with good quality hydraulic ram pumps can actually save around 30% on energy costs, which explains why so many manufacturers continue investing in better pump technology despite the initial expense.

Within the energy field, hydraulic ram pumps play a really important role in getting fluids from one place to another. They create just enough pressure and flow so liquids can move effectively through pipelines and equipment. We see these pumps all over the place in oil drilling operations specifically, since keeping that steady stream going without interruption is absolutely vital for production. Industry rules from groups like the American Petroleum Institute basically tell companies what kind of pumps they need to install based on safety concerns and how well they work under different conditions. What makes hydraulic ram pumps stand out? Well, they're pretty good at pumping large volumes fast. Some newer models can handle thousands upon thousands of gallons each minute while still saving money on running expenses compared to other options. Because of this performance edge, many professionals in the energy business consider them indispensable when managing fluids across various projects.

Good maintenance is really important if we want our hydraulic pumps to last longer. Checking them regularly, swapping out worn seals and filters when needed, and following what the manufacturers recommend makes all the difference. People who know their stuff at the International Fluid Power Society always talk about setting up some kind of preventive maintenance routine so unexpected breakdowns don't happen so often. Some research published in the Journal of Hydraulic Engineering shows that sticking to regular maintenance cuts down on those surprise shutdowns by around 30%, while making the pumps work better overall by maybe 20%. Using genuine parts made by the original equipment manufacturer helps too because they fit properly and work reliably, which means the pumps keep running smoothly for much longer periods without issues.

Getting pressure right in hydraulic systems makes all the difference between smooth operation and major headaches down the road. Most experienced engineers will tell anyone who listens that regular pressure checks, proper installation of relief valves, and keeping an eye on system feedback are pretty much non-negotiable basics. When pressure gets out of whack, things start going wrong fast. We've seen plenty of cases where hoses just snap under stress or entire systems shut down completely, leading to expensive fixes and lost productivity time. The numbers back this up too – studies show that when pressure isn't managed properly, systems can lose around 15% efficiency just from those losses. That's why sticking with these fundamental maintenance routines remains so important for anyone running hydraulic equipment day in and day out.

Putting together IoT and automation is changing how we look at hydraulic pump tech, bringing about better efficiency and control across the board. These smart pumps come packed with sensors and connected features that let operators monitor things in real time while collecting all sorts of useful data. This helps keep everything running smoothly and cuts down on unexpected breakdowns. One major innovation worth mentioning is predictive maintenance systems. They basically figure out when something might need fixing before it actually breaks down, which makes equipment much more reliable and stops those annoying interruptions during operations. Industry folks have been talking about this trend quite a bit lately, and many believe manufacturers and construction companies will start adopting these systems pretty widely around 2025 timeframe. When we combine all these different technologies, what we get are some really solid solutions for dealing with complicated hydraulic problems that were tough to handle before.

As sustainability becomes more important across industries, hydraulic systems are changing how they operate with green alternatives. Many manufacturers now switch to plant-based oils instead of traditional petroleum products while redesigning components to cut down on waste during production. Some companies have started making pumps from aluminum alloys that weigh less and break down easier when disposed of properly. Research indicates these changes can cut greenhouse gas output by quite a bit, which helps factories meet their environmental goals faster. Companies aren't just responding to government regulations either; there's genuine interest in cleaner manufacturing methods throughout the sector. Looking ahead, this trend suggests we'll see even more innovation in fluid power technology as businesses balance profitability with planet friendly approaches.