The rotor plays a really important role in how a vane pump actually works, basically serving as the heart of the whole system that gets things moving when it comes to transferring fluid. As this rotor turns inside the pump housing, those sliding vanes connected to it move back and forth. What makes this setup so clever is how these vanes can adjust themselves to fit against the sides of the pump chamber no matter what position they're in during rotation. This creates that necessary tight seal around the edges which helps create proper suction and keeps the fluid flowing consistently through the system. Anyone who wants to truly grasp why vane pumps are so dependable needs to look at how these parts interact together. The rotor and its sliding companions essentially dance together to push fluids along even when faced with different pressures and conditions across all sorts of industrial settings where hydraulic power matters most.

The way a vane pump works relies heavily on what we call eccentric rotation when it comes to creating pressure inside the system. When the rotor spins off center, those chambers inside actually expand and contract. This changing volume is really important because it creates both pressure and suction at the same time, which keeps the fluid moving continuously through the pump. Most other pump designs don't handle this quite so smoothly. Vane pumps stand out because they deliver fluid with very little pulsation, something that matters a lot in applications where steady flow is absolutely necessary. What makes them special is their capacity to keep delivering that consistent stream even when pressure fluctuates. Take hydraulic cylinders for instance they tend to have much bigger pulsation problems compared to vane pumps, which explains why many engineers prefer vane technology for precision work.

Vane pumps can prime themselves, which makes them work better and get ready faster for operation. When these pumps need to suck fluid into the system, they do it automatically without anyone having to manually intervene. This is really helpful when the pump isn't always sitting in fluid, something that happens quite often in field operations. The automatic priming works great in situations needing quick startup without someone turning valves or filling lines first. Think about mobile hydraulic equipment used on construction sites or agricultural machinery operating in remote areas where technicians might not be nearby. Getting rid of the need for manual priming means fewer breakdowns and delays in getting fluid flowing through the system. That's why so many different industries rely on vane pumps across manufacturing plants, transportation systems, and even some specialized medical equipment applications.

Vane pumps generally fall into two main categories: fixed displacement and variable displacement models, each offering distinct advantages depending on what they need to do. Fixed displacement types push out the same amount of fluid every time the rotor spins around, which works great for setups needing consistent delivery without fluctuations. That's why these pumps show up so often in places like hydraulic presses and power steering systems where reliability matters most. The steady output means operators know exactly what to expect from their equipment during operation, reducing surprises when things get busy on the factory floor.

Variable displacement vane pumps can actually change how much fluid they move depending on what the system needs at any given moment. Because of this ability to adapt, these pumps help save energy across the board, particularly when dealing with workloads that go up and down throughout the day. Many industrial applications rely heavily on such pumps since they handle both pressure changes and flow variations pretty well without sacrificing too much power. They basically strike that sweet spot where machines still perform great but don't waste as much electricity compared to fixed displacement alternatives.

Rotary vane pumps work really well when moving those low viscosity fluids around, which makes them great choices for things like food processing plants. The way these pumps are built lets them handle thin liquids efficiently without causing any emulsification problems that can ruin delicate products. This matters a lot in situations where the product needs to stay intact during transport. Take milk or cooking oil for instance. When moving these kinds of substances through pipelines, it's important not to alter their texture or chemical makeup too much. That's why many dairy farms and oil refineries still rely heavily on this type of pump technology despite newer alternatives being available.

Moreover, these pumps ensure a smooth fluid flow, minimizing pulsation and turbulence, which can be detrimental in precision applications. Their efficiency and reliability make them indispensable in sectors that demand hygienic and consistent fluid transport, underscoring their versatile application potential.

Vane pumps in hydraulic systems form the backbone of most heavy machinery found on construction sites and in mining operations. What sets these pumps apart is their capacity to handle serious pressure without breaking down, which explains why they're so commonly used for things like running those massive hydraulic jacks or keeping big machines moving when the going gets tough. The actual hydraulic power these pumps generate is what keeps all sorts of industrial gear functioning properly, even after hours of continuous operation where other components might start to fail.

The robust performance of hydraulic vane pumps in such environments not only enhances machine efficiency but also prolongs equipment lifespan by ensuring reliable and consistent power delivery. Their integration into industrial machinery underscores their importance in maintaining productivity and efficiency in operations requiring substantial hydraulic power.

In CNC machining setups, vane pumps are essential for handling fluid transfers where accuracy matters most. These pumps keep the flow steady and pressure balanced, which means better cooling and lubrication while machines are running. This helps protect expensive equipment and maintains part quality standards. What makes vane pumps stand out is how they control fluid movement so precisely. Machinists can rely on them to distribute coolant exactly where needed, making operations run smoother and producing parts with tighter tolerances. The stable lubrication provided by these pumps also reduces tool wear significantly. Cutting tools last longer when they're properly lubricated, saving money on replacements over time.

Vane pumps play a key role in the hydraulic systems of oil drilling operations. These devices supply the necessary power for all sorts of drilling activities through control of high pressure hydraulic fluid. Built tough to withstand intense pressures, they keep drilling rigs operating smoothly which makes them vital for getting things done efficiently on site. Anyone working with drilling equipment needs to grasp how these pumps actually work and where they fit into the bigger picture of hydraulic systems if they want their gear to last longer and perform better. When vane pumps manage energy correctly, it boosts overall drilling performance while cutting down maintenance expenses because there's less strain on other parts of the system over time.

Vane pumps play a vital role in high pressure fuel systems because they keep fuel flowing consistently to the engine, which helps maintain good engine performance. They're just as important for lubrication systems too, since getting oil where it needs to go makes all the difference for how long machines last. When these pumps maintain stable pressure and flow rates, they actually stop engines and other mechanical parts from overheating and wearing out prematurely, making everything run more reliably over time. With proper lubricant delivery, moving components can glide past each other without so much friction, and that means equipment stays in service longer before needing replacement parts.

For more details on vane pumps, refer to THM Huade Hydraulics for product specifications and features suited to your industrial applications.

The Variable Vane Pump PV7 was built right into CNC boring and milling machines with one main goal mind: adapting flow rates on the fly so precision machining actually works as intended. What makes this pump stand out? It adjusts fluid delivery exactly when needed during those tricky CNC operations, which means fewer errors and smoother cuts across the board. Plus, the whole thing takes up surprisingly little room on the machine floor. Most shops struggle with tight spaces anyway, so having something that fits neatly without eating up valuable real estate is a big plus for shop managers tracking productivity metrics. Industry pros love how this pump keeps performing reliably day after day without losing steam, something critical when working on parts where even minor deviations can cause major problems downstream.

The hydraulic power system pumps used on oil rigs play a key role in keeping these massive machines moving through tough conditions. Built specifically for the harsh realities of drilling sites, these pumps handle extreme pressures while maintaining reliable operation of all connected equipment. Among them, vane pumps stand out as workhorses in hydraulic systems, delivering consistent force that keeps everything running smoothly even when pressures spike unexpectedly. Their specialized construction allows for precise control over movements across the rig platform, something absolutely essential when positioning heavy machinery or adjusting drill angles. This level of control not only improves overall efficiency but also enhances safety standards during critical energy extraction operations where mistakes can be costly.

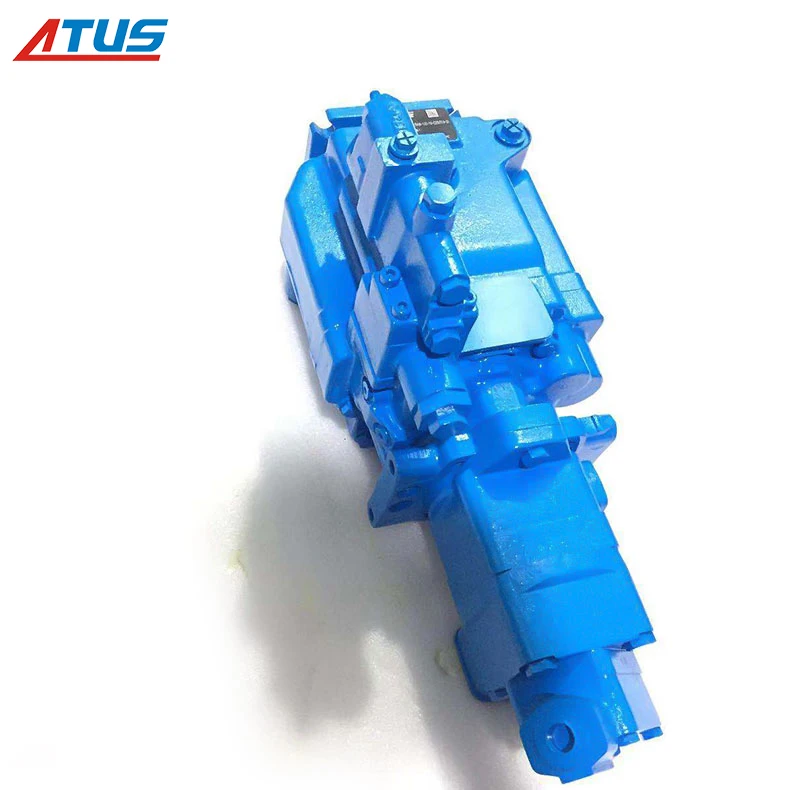

Vickers axial piston pumps really shine because of their tough construction built specifically for heavy duty industrial work. They come in different configurations that make them fit well into bigger system setups where flexibility matters most. The tandem design actually boosts how much fluid they can move at once, which means these pumps handle tough jobs without missing a beat when it comes to keeping fluids flowing continuously. What makes them so reliable is this dual setup that gives operators both good efficiency numbers and dependable operation over long periods of time something factories need when running non stop production lines. Plus there are extra controls on board too, allowing for precise adjustments during operation. That's why many manufacturers across various sectors keep coming back to Vickers pumps whenever they need something solid yet efficient for moving liquids around their facilities day after day.

When it comes to energy efficiency, vane pumps really shine in hydraulic applications because they cut down on both running costs and environmental damage. Their clever design allows these pumps to move fluids around efficiently while using much less power than other types. According to some research done recently, operators have found that switching to vane pumps can actually save about 20 percent in energy usage when compared against older pumping systems. For businesses looking at their bottom line, this means real money savings over time. Plus, from an environmental standpoint, companies adopting vane technology are taking concrete steps toward greener operations since less energy translates into fewer carbon emissions overall.

Want to get more life out of those rotary vane pump parts? Regular maintenance matters a lot, especially sticking to proper lubrication schedules. When we apply lubricant at the right times, it keeps all those moving pieces running without grinding against each other, so they don't wear down as fast. Maintenance folks know that spotting signs of wear before things fall apart makes all the difference. Replacing parts proactively saves tons of time and money later on when equipment breaks down during production. Checking rotor condition and looking closely at vanes during routine inspections helps catch problems while they're still small. Most facilities find that weekly checks work best for catching minor issues before they turn into major headaches.

Spotting and fixing common problems like leaks and pressure drops in vane pumps keeps them running reliably over time. Most leaks happen because the seals wear out after prolonged use, so regular inspections go a long way toward avoiding major repairs down the road. When dealing with pressure issues, technicians need to look inside at parts like valves and chambers where blockages or cracks might be hiding. Troubleshooting usually follows a basic pattern: check each component one by one until everything seems to work properly again. This approach helps maintain good performance whether the pump is used in industrial settings or smaller operations around town.